Dayliff

Great Pumps, Great Value

Dayliff

Great Pumps, Great Value

PRESSFLO

Videos

Notice: Undefined offset: 3 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 4 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 5 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 6 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 7 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 8 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 9 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 10 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 11 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 12 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 13 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 14 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 15 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 16 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 17 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 18 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 19 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 20 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 21 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 22 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 23 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 24 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 25 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 26 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 27 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 28 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 29 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 30 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 31 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 32 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 33 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 34 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 35 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 36 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 37 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 38 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 39 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 40 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 41 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 42 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 43 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 44 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 45 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 46 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 47 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 48 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 49 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 50 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 51 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 52 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 53 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 54 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 55 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 56 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 57 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 58 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 59 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 60 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 61 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 62 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 63 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 64 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 65 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 66 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 67 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 68 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 69 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 70 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 71 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 72 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 73 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 74 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 75 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 76 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 77 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 78 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 79 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 80 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 81 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 82 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 83 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 84 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 85 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 86 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 87 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 88 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 89 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 90 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 91 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 92 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 93 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 94 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 95 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 96 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 97 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 98 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 99 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 100 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 101 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 102 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 103 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 104 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 105 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 106 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 107 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 108 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 109 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 110 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 111 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 112 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 113 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 114 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 115 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 116 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 117 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 118 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 119 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 120 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 121 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 122 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 123 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 124 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 125 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 126 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 127 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 128 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 129 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 130 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 131 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 132 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 133 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 134 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 135 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 136 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 137 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 138 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 139 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 140 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 141 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 142 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 143 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 144 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 145 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 146 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 147 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 148 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 149 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 150 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 151 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 152 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 153 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 154 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 155 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 156 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 157 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 158 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 159 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 160 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 161 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 162 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 163 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 164 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 165 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 166 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 167 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 168 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 169 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 170 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 171 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 172 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 173 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 174 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 175 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 176 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 177 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 178 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 179 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 180 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 181 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 182 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 183 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 184 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 185 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 186 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 187 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 188 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 189 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 190 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 191 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 192 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 193 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 194 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 195 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 196 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 197 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 198 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 199 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 200 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 201 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 202 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 203 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 204 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 205 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 206 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 207 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 208 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 209 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 210 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 211 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 212 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 213 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 214 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 215 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 216 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 217 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 218 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 219 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 220 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 221 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 222 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 223 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 224 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 225 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 226 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 227 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 228 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 229 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 230 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 231 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 232 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 233 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 234 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 235 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 236 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 237 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 238 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 239 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 240 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 241 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 242 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 243 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 244 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 245 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 246 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 247 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 248 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 249 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 250 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 251 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 252 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 253 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 254 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 255 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 256 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 257 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 258 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 259 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 260 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 261 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 262 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 263 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 264 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 265 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 266 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 267 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 268 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 269 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 270 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 271 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 272 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 273 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 274 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 275 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 276 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 277 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 278 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 279 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined variable: furlx in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 163

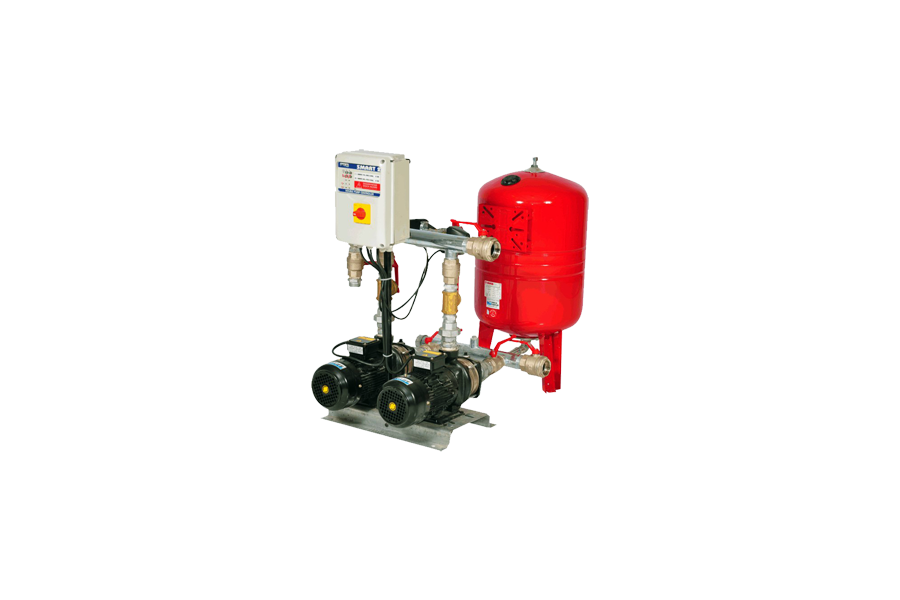

Pressflow

PRESSFLO

Product Overview

Product Details

DAYLIFF Pressure Booster Sets are the effective way to provide continuous water supply to multiple consumer outlets and offer many advantages over gravity supply systems including:-

- Higher line pressures

- Reduced risk of water contamination

- Compact design requires little space

- Elimination of tank structure improves site architecture

- Substantial capital cost savings

Considering these advantages DAYLIFF Booster Sets have been carefully specified for

local conditions and are suitable for all applications from domestic to large institutional

size. Particular features are:-

- Grundfos and Dayliff DE pumps provide optimal operating performance.

- Easy maintenance diaphragm type pressure vessels.

- Comprehensive control panels complete with mains isolator, pump overload

protection and run indicator lights. Optional extras include ammeters, hour

meters and current control relays.

- Bellows operated pressure switches easily adjustable for cut-in and differential operating pressures.

- Compact frame mounted design incorporating necessary valves and piping for simple site installation.

SYSTEMS OPTIONS

Two basic types of systems offered, either for Single or Parallel pump operation.

Single pump systems provide for only one 100% duty pump. This arrangement can be provided with either

one or two pumps, two pump systems operating on a duty/standby basis. Pump changeover can be manual or

automatically alternating after each duty cycle.

Parallel pump systems provide for sequential pump operation including two 50% duty pumps with the second pump operating only at higher demand levels. This arrangement has the advantage of reduced energy consumption and reduced capital cost for a given capacity requirement, though continuity of supply is provided in the event of one pump breakdown. For particular applications special designs incorporating more than two pumps or pumps of different size available.

Properly engineered booster systems provide very considerable advantages over more traditional gravity systems and they are now widely accepted as the most efficient and cost effective method of water distribution. By combining the best quality components and many years experience of system design the DAYLIFF range of booster sets provide performance, reliability and value. With the assured service support of Davis & Shirtliff there is no better solution to water distribution available.

SPECIFICATIONS

All DAYLIFF Booster sets include the following:

Pumps(s):

Grundfos and Dayliff DE centrifugal booster pumps fitted with motors rated for continuous operation.

Pressure Vessel(s):

Vertical fabricated steel pressure vessels with standard rubber diaphragm.

Piping:

Suitably sized piping and fittings are provided for direct suction and delivery line connections including necessary isolating gate valves and non-return valves on the system outlet. The limit of piping is shown in the schematic drawing.

Control Panel:

Panel specification is selected according to pump rating and system configuration. Dayliff Smart 2 electronic controllers are specified for two pump sets, settable for both single and parallel operation, which feature automatic pump changeover, level alarm connections and adjustable motor overload protection. Other panels specifications vary with system model depending upon motor size.

Mounting Frame:

All equipment is mounted on galvanised frame to simplify site installation.