Dayliff

Great Pumps, Great Value

Dayliff

Great Pumps, Great Value

FLA 100

Videos

Notice: Undefined offset: 3 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 4 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 5 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 6 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 7 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 8 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 9 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 10 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 11 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 12 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 13 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 14 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 15 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 16 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 17 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 18 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 19 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 20 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 21 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 22 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 23 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 24 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 25 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 26 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 27 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 28 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 29 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 30 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 31 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 32 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 33 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 34 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 35 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 36 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 37 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 38 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 39 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 40 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 41 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 42 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 43 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 44 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 45 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 46 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 47 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 48 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 49 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 50 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 51 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 52 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 53 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 54 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 55 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 56 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 57 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 58 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 59 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 60 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 61 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 62 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 63 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 64 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 65 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 66 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 67 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 68 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 69 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 70 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 71 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 72 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 73 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 74 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 75 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 76 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 77 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 78 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 79 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 80 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 81 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 82 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 83 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 84 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 85 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 86 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 87 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 88 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 89 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 90 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 91 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 92 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 93 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 94 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 95 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 96 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 97 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 98 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 99 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 100 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 101 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 102 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 103 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 104 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 105 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 106 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 107 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 108 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 109 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 110 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 111 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 112 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 113 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 114 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 115 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 116 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 117 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 118 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 119 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 120 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 121 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 122 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 123 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 124 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 125 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 126 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 127 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 128 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 129 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 130 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 131 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 132 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 133 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 134 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 135 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 136 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 137 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 138 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 139 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 140 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 141 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 142 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 143 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 144 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 145 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 146 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 147 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 148 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 149 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 150 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 151 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 152 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 153 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 154 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 155 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 156 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 157 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 158 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 159 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 160 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 161 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 162 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 163 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 164 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 165 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 166 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 167 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 168 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 169 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 170 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 171 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 172 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 173 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 174 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 175 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 176 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 177 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 178 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 179 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 180 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 181 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 182 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 183 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 184 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 185 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 186 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 187 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 188 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 189 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 190 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 191 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 192 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 193 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 194 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 195 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 196 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 197 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 198 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 199 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 200 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 201 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 202 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 203 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 204 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 205 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 206 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 207 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 208 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 209 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 210 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 211 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 212 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 213 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 214 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 215 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 216 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 217 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 218 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 219 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 220 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 221 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 222 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 223 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 224 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 225 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 226 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 227 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 228 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 229 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 230 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 231 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 232 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 233 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 234 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 235 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 236 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 237 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 238 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 239 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 240 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 241 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 242 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 243 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 244 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 245 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 246 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 247 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 248 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 249 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 250 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 251 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 252 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 253 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 254 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 255 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 256 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 257 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 258 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 259 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 260 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 261 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 262 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 263 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 264 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 265 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 266 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 267 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 268 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 269 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 270 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 271 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 272 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 273 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 274 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 275 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 276 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 277 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 278 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined offset: 279 in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 111

Notice: Undefined variable: furlx in /home/daylibjd/public_html/templates/t3_bs3_blank/tpls/blocks/hikashop-product.php on line 163

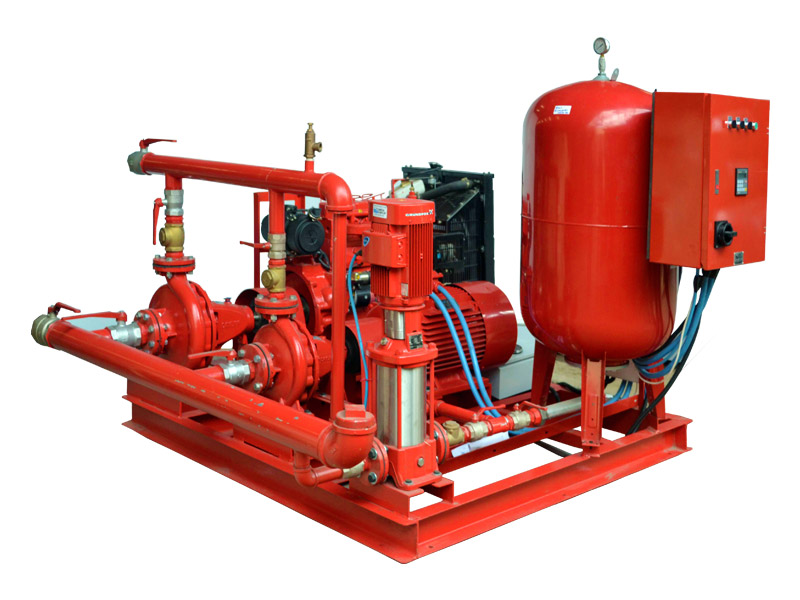

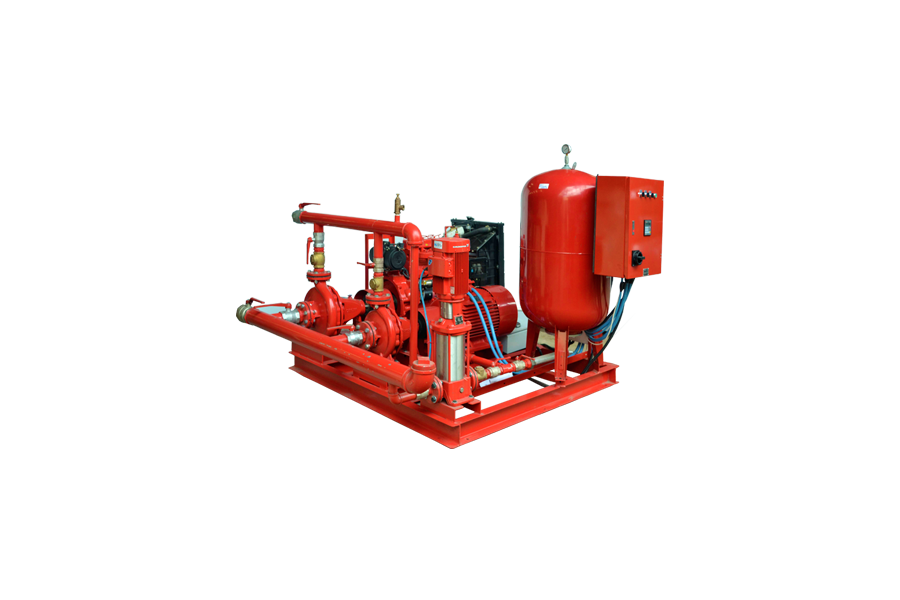

Fla100

FLA 100

Product Overview

Product Details

DAYLIFF FLA packaged Fire Sets are specially designed to provide automatic supply to multiple hose reel or sprinkler outlets for firefighting installations. Standard sets combine parallel duty diesel and electric powered supply pumps to ensure serviceability in all conditions as well as a jockey pump to maintain system pressure. Particular features include:-

- Individual electric motor and Lister diesel engine powered Ajax pumpsets providing standby supply in the event of electrical power failure

- Separate automatic jockey pump to maintain system pressure and regulate main pump operation Bellows type pressure switch controlled operation providing progressive jockey pump, electric pump and diesel pump starting at reducing cut-in pressure

- Low maintenance diaphragm type pressure vessel to regulate pump cycling.

- Integral control panel providing automatic parallel operation of the supply pumps and incorporating electrical protection and a DC battery charging system

- Compact frame mounted design incorporating necessary valves and piping for simple site installation.

3 Systems are designed to give their rated output at 5 Bar and three standard sizes are available, 40, 60 and 100 m /hr with the two pumpsets operating in parallel, 50% standby output being provided in the event of electrical failure. For particular applications special designs incorporating different equipment arrangements and specifications are available.

For all firefighting applications high levels of equipment performance and dependability are vitally important for the protection of both lives and property. Dayliff FLA Fire Sets combine quality components, all carefully matched for optimal operational efficiency with Davis and Shirtliff's unmatched pumping expertise and competitive pricing to provide effective, reliable and easy to install firefighting solutions.

For all firefighting applications high levels of equipment performance and dependability are vitally important for the protection of both lives and property. Dayliff FLA Fire Sets combine quality components, all carefully matched for optimal operational efficiency with Davis and Shirtliff's unmatched pumping expertise and competitive pricing to provide effective, reliable and easy to install firefighting solutions.

SPECIFICATIONS

Supply Pumps: Dayliff single stage end suction pumps featuring gland packing seal and heavy duty bearings constructed from heavy duty cast iron with bronze impellers. Pumps models are selected to meet the design pressure and flow rates. Detail performance curves are available on request.

Diesel Engine: Lister TR naturally aspirated air-cooled diesel engines fitted with automatic electric start, engine mounted 13.5l fuel tank and a dual 50Ah battery set.

Electric Motor: TEFC squirrel cage 2-pole 2900 rpm electric motors suitably rated for the pump load.

Jockey Pump: Grundfos CH4-60 horizontal multistage centrifugal pump fitted with 1kW electric motor. The pump is set to maintain system pressure at 4.5Bar thus avoiding cycling of the service pumps due to minor system leakages.

Pressure Vessel: Varem 300 litre vertical pressure vessel fitted with butyl rubber diaphragm. The oversized vessel volume limits jockey pump cycling frequency to a maximum of 10 starts per hour.

Piping: Suitably sized piping and fittings are provided for direct suction and delivery line connections including necessary isolating gate valves, non-return valves on the system outlet. The limit of piping is shown in the schematic drawing.

Control Panel: Control panel incorporating incoming mains isolator and MCB, voltage control relay, MCB and star-delta starter for the main pump, MCB and DOL starter for the jockey pump, pump run/trip/no water indicators, 12-Volt DC power circuit for the engine and a DC battery charging system. The panel is integrally mounted as standard, though can be supplied loose for remote installation if required.

Supply Pumps: Dayliff single stage end suction pumps featuring gland packing seal and heavy duty bearings constructed from heavy duty cast iron with bronze impellers. Pumps models are selected to meet the design pressure and flow rates. Detail performance curves are available on request.

Diesel Engine: Lister TR naturally aspirated air-cooled diesel engines fitted with automatic electric start, engine mounted 13.5l fuel tank and a dual 50Ah battery set.

Electric Motor: TEFC squirrel cage 2-pole 2900 rpm electric motors suitably rated for the pump load.

Jockey Pump: Grundfos CH4-60 horizontal multistage centrifugal pump fitted with 1kW electric motor. The pump is set to maintain system pressure at 4.5Bar thus avoiding cycling of the service pumps due to minor system leakages.

Pressure Vessel: Varem 300 litre vertical pressure vessel fitted with butyl rubber diaphragm. The oversized vessel volume limits jockey pump cycling frequency to a maximum of 10 starts per hour.

Piping: Suitably sized piping and fittings are provided for direct suction and delivery line connections including necessary isolating gate valves, non-return valves on the system outlet. The limit of piping is shown in the schematic drawing.

Control Panel: Control panel incorporating incoming mains isolator and MCB, voltage control relay, MCB and star-delta starter for the main pump, MCB and DOL starter for the jockey pump, pump run/trip/no water indicators, 12-Volt DC power circuit for the engine and a DC battery charging system. The panel is integrally mounted as standard, though can be supplied loose for remote installation if required.

OPERATIONAL DATA

|

Model |

Nominal Flow (m3/hr) |

Diesel Pump |

Electric Pump |

Piping Size |

Wt (kg) |

|||||||||

|

Parallel Duty |

Single Duty |

Pump |

Engine |

Power (kW) |

Speed (rpm) |

Output (m3/hr) |

Head (m) |

Pump |

Motor (kW) |

Output (m3hr) |

Head (m) |

|||

|

FLA 100 |

100 |

50 |

DE 50-20 |

KD625.2 |

17.1 |

3000 |

61 |

55 |

DE 50-20 |

15 |

61 |

55 |

4” |

665 |